The Tennant T16 Parts Manual is an essential guide for maintaining and repairing the Tennant T16 rider scrubber‚ providing detailed diagrams‚ component lists‚ and troubleshooting solutions to ensure optimal performance and longevity of the equipment․

Overview of the Tennant T16 Rider Scrubber

The Tennant T16 is a battery-powered‚ ride-on autoscrubber designed for industrial and commercial cleaning․ It features an intuitive control system integrated into the steering wheel‚ allowing operators to adjust settings and monitor functions effortlessly․ Built for versatility‚ the T16 is suitable for cleaning both rough and smooth surfaces‚ including concrete‚ tile‚ and synthetic materials․ Its robust design ensures durability‚ while its advanced engineering minimizes downtime and maximizes productivity․ The machine is equipped with essential components like recovery tanks‚ vacuum fans‚ and squeegees‚ which work together to deliver efficient cleaning results․ Understanding the T16’s features and functionality is crucial for effective operation and maintenance‚ making the parts manual an indispensable resource for users․

Importance of the Parts Manual for Maintenance and Repair

The Tennant T16 parts manual is a vital resource for ensuring the optimal performance and longevity of the equipment․ It provides detailed diagrams‚ component lists‚ and repair instructions‚ enabling users to identify and replace parts accurately․ Regular maintenance‚ as outlined in the manual‚ helps prevent unexpected breakdowns and extends the lifespan of the scrubber․ Troubleshooting guides within the manual allow operators to quickly diagnose and resolve issues‚ minimizing downtime․ By following the manual’s instructions‚ users can ensure that repairs are done safely and effectively‚ using genuine or equivalent parts recommended by Tennant․ This not only maintains the machine’s functionality but also guarantees operator safety and efficiency․

Key Components of the Tennant T16

The Tennant T16 includes a robust battery-powered system‚ intuitive control panel‚ durable scrubbing deck‚ and high-efficiency squeegee mechanism‚ ensuring reliable performance for industrial cleaning tasks․

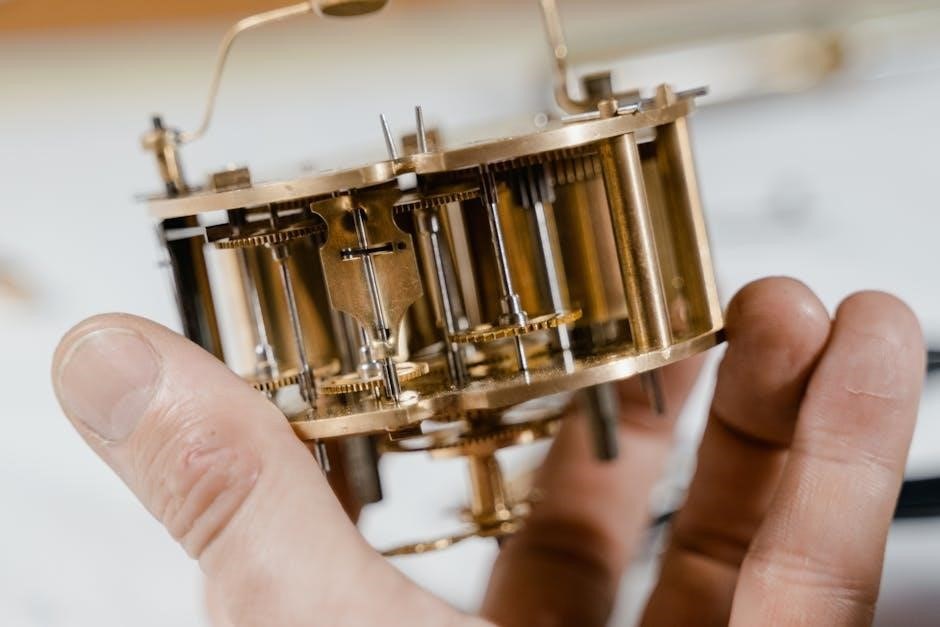

Major Assemblies and Their Functions

The Tennant T16 is composed of several major assemblies‚ each designed for specific functions․ The scrubbing deck is responsible for cleaning surfaces‚ utilizing brushes or pads for effective dirt removal․ The squeegee mechanism ensures water and debris are collected efficiently‚ preventing streaks․ The control system‚ integrated into the steering wheel‚ provides operators with intuitive command over speed‚ water flow‚ and brush pressure․ The recovery tank stores dirty water‚ while the solution tank holds cleaning agents for distribution․ The battery compartment powers the machine‚ offering extended runtime for large areas․ These assemblies work together seamlessly to deliver high-performance cleaning in industrial and commercial environments․ Proper maintenance of each component is crucial for sustained functionality and reliability․

Identifying Critical Spare Parts and Accessories

The Tennant T16 requires specific spare parts and accessories to maintain optimal performance․ Brushes‚ squeegees‚ and motors are among the most critical components‚ as they directly impact cleaning efficiency․ The parts manual provides detailed diagrams and lists to help identify these essentials․ Regularly replacing worn brushes and squeegees ensures effective dirt and water removal․ Additionally‚ key electrical components like control panels and sensors should be monitored for wear․ Proper identification of part numbers from the manual ensures accurate ordering․ Operators should always use OEM or equivalent parts to maintain machine reliability and longevity․ This approach prevents downtime and ensures the T16 continues to deliver consistent results․

Maintenance and Troubleshooting Guide

This section provides step-by-step instructions for routine inspections‚ diagnosing common issues‚ and repairing the Tennant T16 efficiently using the parts manual as a reference guide․

Routine Maintenance Procedures

Regular maintenance is crucial for extending the lifespan of the Tennant T16․ Begin with daily checks: inspect brushes‚ squeegees‚ and filters for wear or damage․ Clean debris from recovery tanks and vacuum fans to ensure proper function․ Charge the battery fully after each use and avoid over-discharging․ Monthly‚ check fluid levels‚ lubricate moving parts‚ and inspect electrical connections for damage or corrosion․ Refer to the parts manual for specific part numbers and diagrams․ Replace worn components promptly to prevent further damage․ Follow the recommended schedule in the manual to maintain optimal performance and reduce downtime․ Always use genuine Tennant parts for reliability and safety․

Common Fault Codes and Solutions

The Tennant T16 parts manual provides a comprehensive list of fault codes and solutions to help operators troubleshoot issues efficiently․ Common fault codes include errors related to battery voltage‚ hydraulic system malfunction‚ or debris buildup in the recovery tank․ For example‚ a “Low Battery” alert indicates the battery needs charging‚ while a “Hydraulic Overheat” code suggests checking fluid levels or inspecting for blockages․ Refer to the manual for specific fault code definitions and step-by-step solutions․ Always use genuine Tennant parts for repairs to ensure compatibility and safety․ Regularly reviewing the fault code section can help prevent downtime and extend the lifespan of your equipment․

How to Order Parts for the Tennant T16

To order parts‚ identify the machine model and serial number from the data plate‚ then reference the parts list in the manual․ Use genuine Tennant parts for compatibility and safety․

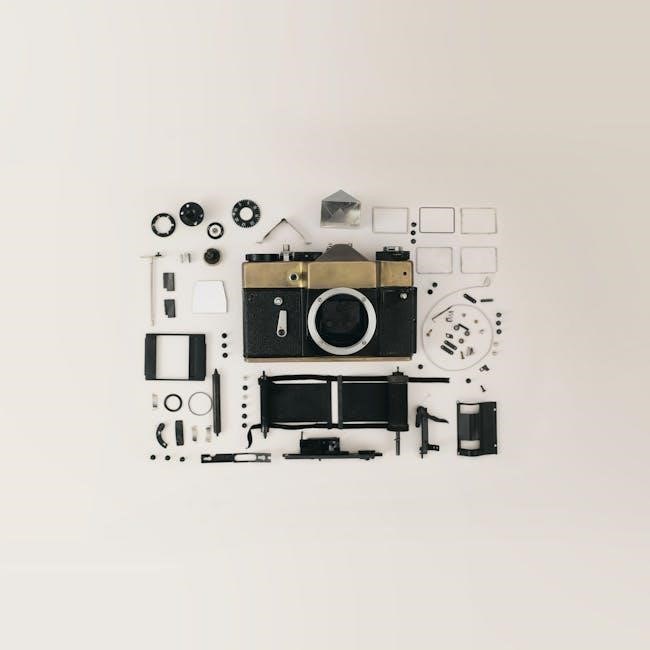

Understanding the Parts List and Diagrams

The parts list and diagrams in the Tennant T16 manual provide a detailed breakdown of components‚ enabling users to identify and locate parts efficiently․ Each diagram is labeled with part numbers‚ descriptions‚ and quantities‚ ensuring clarity․ Symbols and numbering systems guide users through assembly and disassembly processes․ Cross-referencing parts with the list helps in verifying compatibility and availability․ The manual also highlights essential tools and materials required for repairs․ By understanding these resources‚ operators can streamline maintenance and ensure accurate ordering of replacement parts․ Always refer to the official Tennant T16 parts list and diagrams for precise identification to avoid errors․ This ensures safety and optimal equipment performance․

Step-by-Step Guide to Ordering Replacement Parts

To order replacement parts for the Tennant T16‚ start by identifying the required part number using the parts list or diagrams in the manual․ Next‚ visit the Tennant website or contact an authorized dealer to check availability․ Ensure the part is compatible with your specific T16 model by referencing the serial number on the data plate․ Place your order by providing the part number and machine details to the supplier․ For accuracy‚ double-check all information before confirming․ Using genuine Tennant parts ensures optimal performance and longevity of your equipment․ Follow these steps to streamline the process and maintain your T16 efficiently․

Safety Precautions and Operating Guidelines

Always wear protective gear and follow pre-operational checks to ensure safe operation of the Tennant T16․ Adhere to guidelines to prevent accidents and maintain equipment integrity․

Essential Safety Measures for Operators

Operators must prioritize safety by wearing protective gear‚ including gloves and eyewear‚ when operating the Tennant T16․ Ensure proper training is completed before use to understand all controls and functions․ Always conduct pre-operational checks to verify the machine’s integrity and functionality․ Avoid operating the scrubber in hazardous environments or near open flames․ Use approved cleaning agents and follow chemical handling guidelines to prevent accidents․ Regularly inspect batteries and electrical components to avoid malfunctions․ Never overload the machine beyond its specified capacity‚ as this could compromise stability and safety․ Familiarize yourself with emergency shutdown procedures and keep the operating area clear of obstacles․ Adhere to all safety guidelines to protect both the operator and the equipment․

Pre-Operational Checks and Best Practices

Before operating the Tennant T16‚ perform a thorough inspection to ensure all components are secure and functioning properly․ Check battery levels and fluid levels‚ and ensure the recovery tank is empty․ Inspect the squeegee and brushes for wear or damage‚ replacing them if necessary․ Test all controls to confirm they respond correctly and adjust settings as needed; Always review the operator manual to familiarize yourself with best practices and safety guidelines․ Conduct a trial run in a safe area to verify machine performance․ Regular pre-operational checks help prevent unexpected issues and ensure efficient cleaning operations․ Follow these practices consistently to maintain equipment reliability and operator safety․

The Tennant T16 parts manual is a vital resource for maximizing efficiency and extending equipment lifespan․ By following its guidance‚ operators ensure optimal performance‚ safety‚ and durability․

Maximizing Efficiency with Proper Parts Management

Proper parts management is crucial for maintaining the Tennant T16’s performance and longevity․ By understanding the parts manual‚ operators can quickly identify and replace worn or damaged components‚ reducing downtime․ Regularly referencing diagrams and component lists ensures accurate ordering and installation․ Keeping a stock of critical spare parts on hand minimizes delays during repairs․ Additionally‚ adhering to maintenance schedules and troubleshooting guides helps prevent unexpected breakdowns․ Using Tennant-authorized parts guarantees compatibility and reliability‚ ensuring the machine operates at peak efficiency․ Proper parts management not only enhances productivity but also extends the lifespan of the Tennant T16‚ making it a cost-effective solution for industrial cleaning tasks․

Final Tips for Extending Equipment Lifespan

To maximize the lifespan of the Tennant T16‚ regular lubrication of moving parts and thorough cleaning of components are essential․ Proper storage in a dry‚ clean environment and maintaining the battery charge level can prevent degradation․ Always use Tennant-authorized parts to ensure compatibility and durability․ Training operators on proper usage and maintenance routines can significantly reduce wear and tear․ Additionally‚ documenting maintenance schedules and repair history helps track the machine’s condition over time․ By following these practices‚ users can ensure the Tennant T16 operates efficiently for years‚ minimizing downtime and extending its service life effectively․ Consistent care and attention to detail are key to optimizing its performance and longevity․